Over the years, office chairs have become more of a necessity than a luxury because of the benefits they provide. And there has been a significantly increasing demand for them, especially now that people are forced to work home.

Out of all the pieces of furniture in homes and workplaces, an office chair is perhaps one of the most underrated. Yes, we use them almost 10 hours every day, but do we appreciate them enough?

Did you know that much hard work and labor hours go into designing and building just one office chair? Have you ever wondered how they are made?

When you think of how many hours you’ve sat and worked but felt minimal body aches, you probably have a reliable office chair to thank.

Today, we will walk you through the manufacturing process of an office chair. If you’ve ever been curious about what it takes to build your trusty work partner, then read on.

How are office chairs manufactured?

It starts with constructing the chair’s structure, which consists of the back and the base. The next step is the creation of the upholstery for the backrest and the seat. The next step is installing the mechanism for the seat’s height and tilt adjustments, followed by the cylinder and the caster. The final step is assembly.

Before we talk about how office chairs are made, though, let’s quickly discuss their history.

Table of Contents

The History of an Office Chair

The swiveling mechanism of office chairs was the brainchild of one of America’s founding fathers, Thomas Jefferson. It is believed that the first-ever swivel chair was where he sat as he drafted the United States Declaration of Independence in 1776.

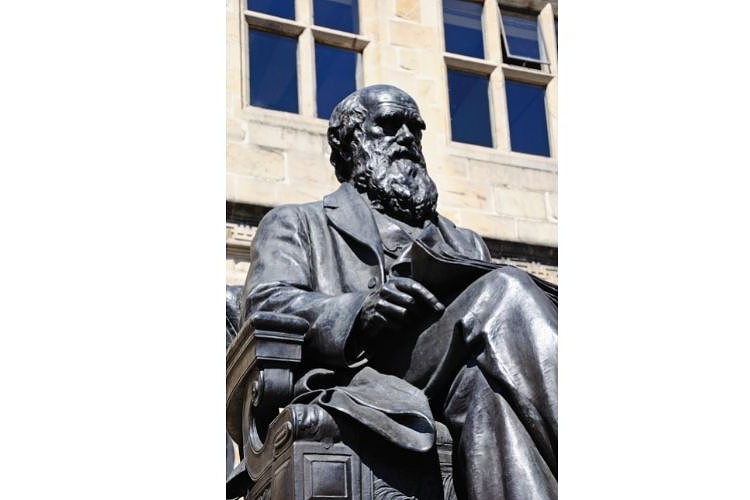

Then, in 1840, famous naturalist Charles Darwin innovated his office chair by putting small wheels or casters on its legs to enable him to move around and get to his specimens quickly as he worked on the theory of evolution.

Ergonomics came into the picture in the 1970s with the invention of the revolutionary Ergon chair by Herman Miller and Bill Stumpf. It was a chair designed to sustain physical health and improve the comfort of an office worker.

Today, Herman Miller is one of the leading office chairmakers in the world. The company’s iconic Aeron chair is the best-selling office chair across the globe.

It won the Industrial Design Council of Australia’s “Good Design Award” in the Furniture and Lighting category.

How are office chairs made in mass production?

You would think that in this modern age, office chairs in mass production are 100% machine-made. However, that is not the case as they are products of human labor and craftsmanship more than they are factory goods.

Building one chair requires several workers, each doing a specific job. Like puzzle pieces that come together, their combined efforts create a unique piece that will make someone’s office job a lot more comfortable.

Building the office chair structure

The process begins when a worker creates the office chair’s structure.

They use a hydraulic-powered machine to bend 14-gauge steel tubing to form the bottom cushion frame. Then, they join the ends and weld steel bars that will support the seat adjustment mechanism.

Then, they clip sinuous springs from the front to the back of the steel frame. The S-shaped springs provide a flexible web of suspension similar to that of a coiled seat.

The worker also places rods laterally and clips them to the springs for additional support.

Now that the frame is complete, another worker begins building the back frame, which includes the lumbar support, armrests, and other parts depending on the design of the office chair. They grind the rough spots from the steel and then combine the bottom and the back frames.

Creating the upholstery

A worker from the upholstery department begins by smoothing the leather on a table. Then, they cut patterns using cardboard templates.

The worker cuts carefully to get the size of the leather they need for one chair and minimize waste. They see that they cut leather from the same large piece of hide to make sure the chair’s upholstery has consistent color and texture.

Another worker collects the leather patterns and cuts foam cushioning for the backrest of the chair. They will use a more rigid foam for the contoured cushioning and a soft one for the backrest.

Depending on the design of the backrest, the worker will cut slits into the foam to create channels or narrow canals that will become a design feature. Then, they will draw lines to the corresponding leather using chalk.

Another worker aligns chalk lines in the leather with the slits and puckers the leather while sewing the back to it, forming a ribbed pattern. Then, they stitch the padding flat to other pattern pieces, such as the side panel for the backrest and the seat.

Once leather-covered paddings are complete, other workers will add a chipboard panel to encase the office chair’s structure with foam. Then, they cover it with upholstery.

Office chair assembly

Once the upholstery is done, the last step is assembly.

A worker installs a cover on the bottom of the seat and screws a sliding plate to it. Then, they will attach a mechanism that will work with the plate to allow the seat to slide forward or back.

This mechanism will also adjust the height and the tilt of the seat. The worker will then install the hydraulic cylinder, which will serve as the chair’s stem.

Next is the installation of the swivel, which will allow the chair to rotate 360 degrees. The worker will then attach an aluminum base to the cylinder and snap the casters or the small wheels into the aluminum base’s slots.

Typically, there are five casters in an office chair.

Finally, the worker will attach the remaining parts, such as the headrest and the armrests.

How long does it take to manufacture an office chair

Depending on the manufacturer, an office chair can take up to four or five weeks to build. However, the lead time can extend several more weeks if the chair requires any customization.

What materials are office chairs made of?

Unlike regular ones like dining chairs, office chairs are made up of a wide variety of materials. Each part is meticulously designed and crafted to ensure comfort and sitting posture support.

Below are the most commonly used materials in office chairs:

Leather

While the seat and the inner workings of the chair are what matter best, it’s the upholstery fabric that makes a lasting impression. Leather is perhaps the number one choice of material for upholstery fabrics because it oozes luxury and sophistication.

Leather is also reasonably easy to clean and maintain. It is also durable and comfortable, so it is the go-to material, especially for executive chairs.

The main drawback with leather, however, is its cost. Office chairs that come in leather backs and seats are often more expensive than others.

Mesh

Mesh is another popular material for office chairs. It is breathable as the tiny holes in the mesh give you enough airflow while you work.

Not only does mesh enhance your decor, but it also improves a chair’s ergonomics through its flexibility. It conforms to the shape of your body and correctly supports your spine.

There are different types of mesh now in the market, including Nylon and Knitted Mesh. The latter is preferred because nylon usually causes abrasions on clothes due to friction.

Plastic

Some office chairs come with armrests, bases, and even casters made of plastic.

While plastic is not as durable as other materials, it lasts quite a long time. However, because it is lightweight, over time, some parts such as armrests may rattle.

Office chairs that are made of plastic components are often compact and affordable.

Steel

Steel is a solid and durable office chair material. Many office chairs have structures, stems, and casters made of steel.

While steel is more commonly used, aluminum is still the best material for office chair bases.

Conclusion

Office chairs are indeed some of the best inventions ever. Not only do they make sitting more comfortable, but they also make a huge difference in our lives.

Office chairs are known to improve the way you work by reducing the risks of back and shoulder pains, correcting your posture, and contributing to your overall health. They also help you increase your productivity by ensuring you sit at an optimal angle while you work.

The world has evolved, and now, office chairs aren’t just pieces of furniture. They are also tools that significantly improve our daily lives.

Learning about how they are made can humble us and teach us an important lesson: not take even the most straightforward thing for granted.

Be grateful if you have an office chair that decreases discomfort when you need to sit for long hours. But if you don’t have one, now would probably be the best time to buy one.

My name is Vance, and I am the owner of To Ergonomics. Our mission is to improve your workflow by helping you create a supportive and welcoming environment. We hope that you’ll find what you’re looking for while you’re here.